Drill Cool's

FRESHWATER GEO‑COOLER™

THE ORIGINAL MUD COOLER

THE GEO‑COOLER™ IS THE PERFECT SOLUTION FOR LAND BASED DRILLING WITH ACCESS TO FRESH WATER.

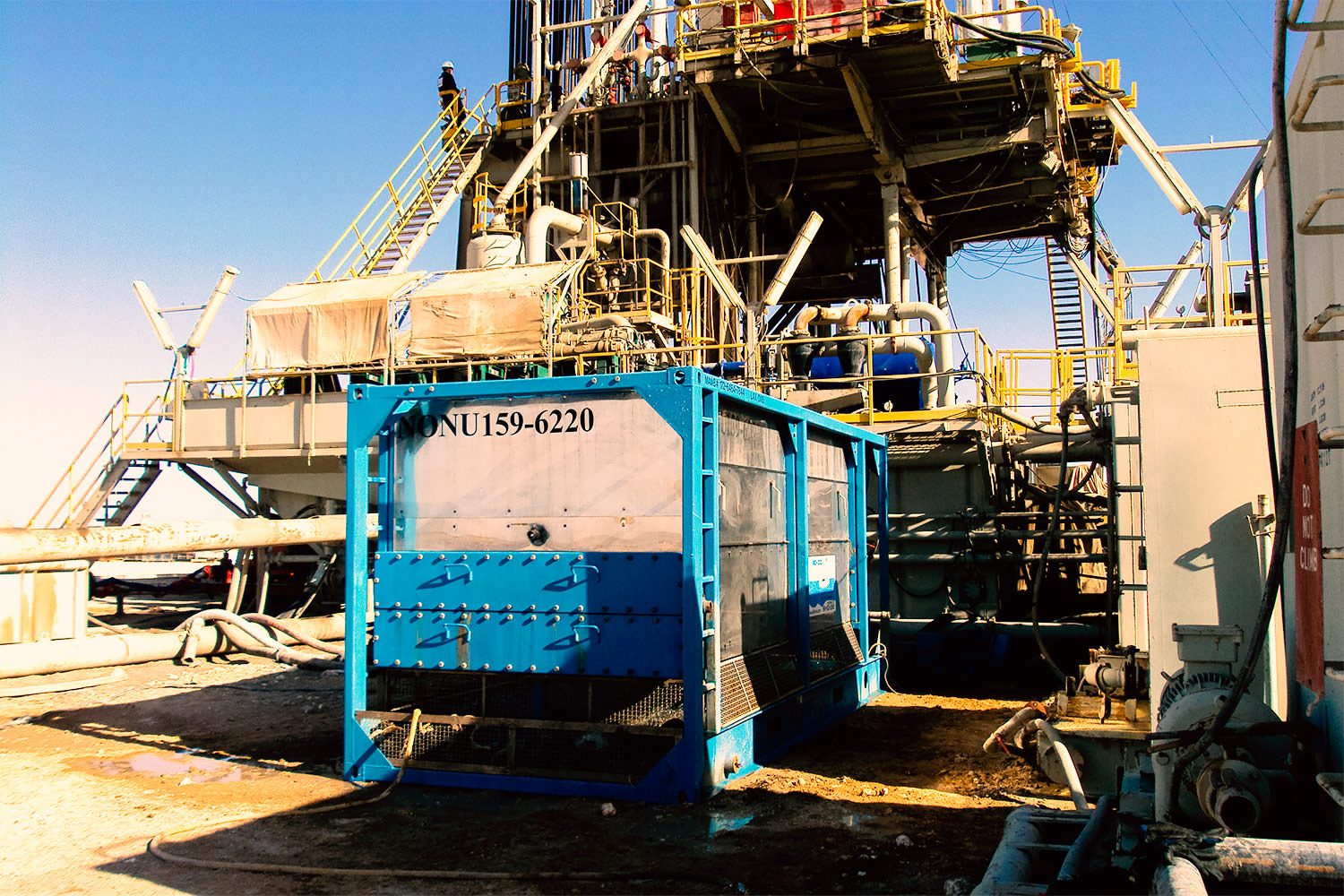

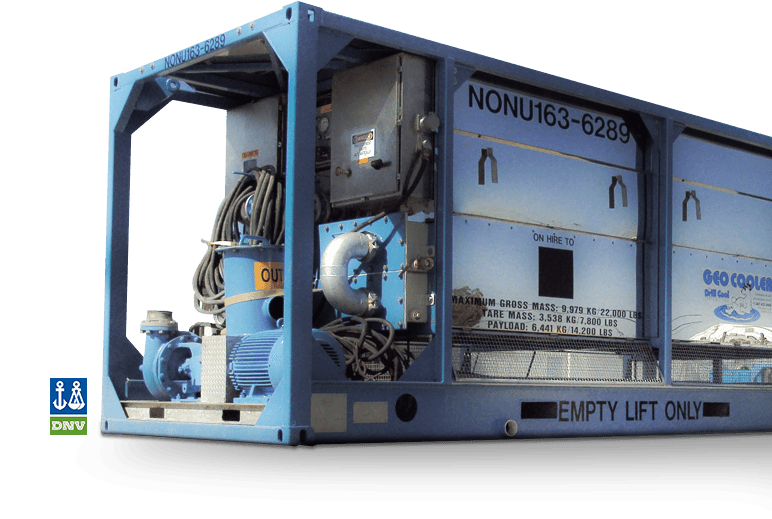

The Freshwater Geo‑Cooler™ is the industry standard for mud cooling needs in all HPHT and geothermal drilling areas of the world – both onshore and offshore. This proprietary mud cooler design incorporates the power and efficiency of a closed circuit cooling tower with the robust versatility of a DNV certified offshore ISO container – thus enhancing the mobility and flexibility of the drilling fluid temperature control system. Many of our customers have realized significant savings by sharing their Geo‑Coolers™ across onshore and offshore drilling programs within the same region.

AVAILABLE IN SKID, CONTAINER & TRAILER MOUNTED MODELS

FRESHWATER GEO‑COOLER™ BENEFITS

- Rugged design for months of maintenance free operation – even without a dedicated operator

- Excellent heat transfer efficiencies over the widest flow rates

- Proven reliability over thousands of installations

- Engineered for all drilling fluids (> 20 ppg fluid & > 20 mm diameter solids)

- 20′ offshore iso container, skid & trailer mounted models available – Modular design ships anywhere in the world (land, sea or air – the bear goes everywhere)

- Staged across the globe – ready for immediate mobilization

HEAVY FLUIDS DESIGN

High Solids Content

MUD FLOW

800 GPM / 3028 LPM

WATER CONSUMPTION

3 GPM / 11.3 LPM

ELECTRICAL

High Solids Content

L x W x H

20′ x 8′ x 8′6″

6.1m x 2.4m x 2.6m

WEIGHT

22,000LBS / 9,797KG

More about the Geo‑Cooler™

With more than 35 years of dedicated mud cooling experience in the Oil & Gas and Geothermal Drilling Industry, Drill Cool Systems is the only company that can offer the innovation, expertise, engineering, and equipment required on the most critical and difficult high temperature wells.

The first mud cooler was successfully developed and deployed by the founder of Drill Cool Systems for the Geothermal Industry in the late 1970s. The benefits of the mud cooler to the rig and associated equipment quickly spread to the Oil & Gas Industry especially in the early HPHT gas wells in the Gulf of Mexico. The design quickly evolved to the first Geo‑Cooler™ that was purpose built by Drill Cool Systems for the offshore industry. The 20ft Freshwater Geo‑Cooler quickly grew as the industry standard for mud cooling needs throughout the Gulf of Mexico, Southeast Asia, Middle East, Australia and Japan along with other high temperature areas of the world.

The Geo‑Cooler™ has continuously served the international high temperature drilling industry for more than 20 years. The ultra-portability, robustness, and flexibility of these drilling fluid temperature control systems continue to prove a valuable essential component of any onshore or offshore drilling program.

Geo‑Cooler™ Case Studies

Drill cool systems has successfully bridged that chasm between risk characterization, innovation and application by coupling their vast expertise in high temperature drilling and heat transfer with the ability to listen, analyze, and solve their customers’ high temperature problems that are unique to each well.

These Well Temperature Control™ solutions have helped mitigate our customer’s temperature related risks and have contributed to the success of these - time and time again. Please review some of our case studies.

HIGH TEMPERATURE DRILLING OPERATIONS

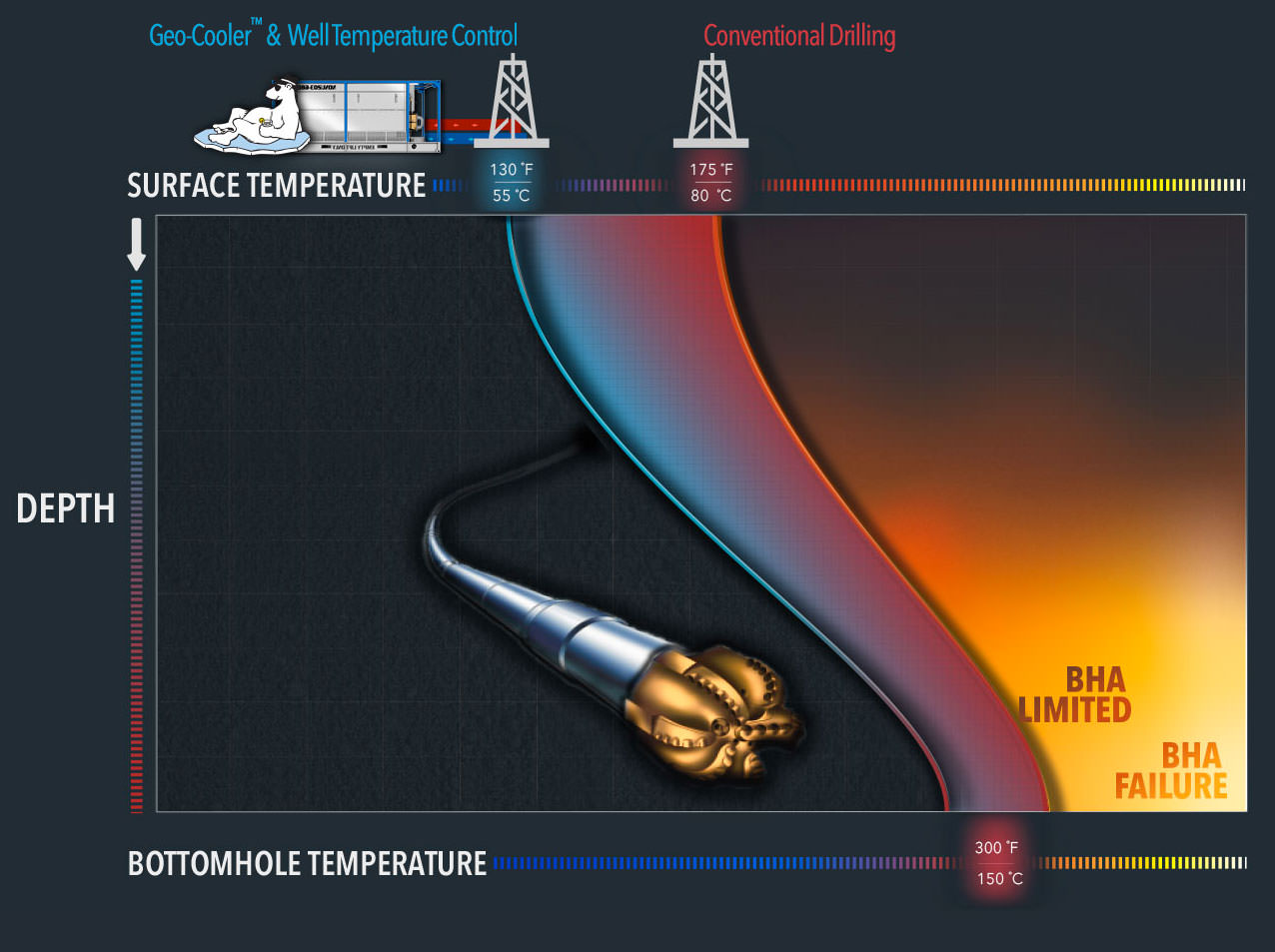

Well Temperature Control™ vs Conventional Drilling

As wells grow in complexity, the need to characterize the temperature, pressure and energy within the drilling system also increases. Parameters such as hole size, flow rate, drilling fluid type, and geothermal gradient all can have a direct thermal impact on the well being drilled and affect your ability to safely and successfully complete the well.

Need Help Choosing the right solution?

Utilize the DCS Equipment Selector Tool