Drill Cool's

ENGINEERING SERVICES

EXPERIENCE & INNOVATION PROVIDING A DISTINCT VALUE TO EACH OF OUR CUSTOMERS

DRILL COOL SYSTEMS, INC. IS THE LEADER IN WELL TEMPERATURE CONTROL™ & MANAGED TEMPERATURE DRILLING™

With more than 35 years of oil & gas and geothermal drilling industry experience, Drill Cool Systems is the only company that offers a distinctive synergy of high temperature drilling expertise and knowledge with the vastest selection of proven drilling fluid temperature control equipment.

Empowered with innovation, experience, and the best mud cooling equipment, the team at Drill Cool Systems continues to make each high temperature drilling environment safer and more efficient. From the hottest geothermal wells, the deepest HPHT wells, and the most difficult wellbore temperature control wells of the arctic permafrost — Drill Cool Systems is the solution to your Well Temperature Control problems.

FULLY INTEGRATED SOLUTIONS TO THE

HEAT AND TEMPERATURE RELATED RISKS

ASSOCIATED WITH YOUR DRILLING PROGRAM

DEVELOP SOLUTIONS

Drill Cool Systems establishes relationships with their customers that allow them to develop comprehensive solutions that are optimized for their specific wells and needs. Coupling a wealth of field and practical experience with proven technology, the team at Drill Cool Systems has helped their customers successfully complete wells in the most harsh and difficult drilling conditions. This is evident with the continuous evolution of their processes and technology over more than 30 years.

Drill Cool Systems continues to be The Leader in Well Temperature Control by applying their extensive experience to design, fabricate, operate, and manage their Managed Temperature Solutions throughout the world. Not only has Drill Cool Systems been integral in High Temperature (HT) Drilling, but continues to grow in all areas of drilling within the Oil & Gas Industry including SAGD, permafrost drilling, hydrate drilling, and unconventional shale. The technology and processes developed specifically for these fields have grown to directly benefit the HPHT industry.

COLLABORATIONS WITH DRILLING TEAMS

Implementing the right solution with the customer involves much more than delivering equipment to the job site and operating the equipment for the duration of the project.

The Drill Cool System allows DCS Engineers to work with the entire drilling team, even from the inception of the well, to ensure temperatures have properly been predicted and managed throughout the entire system. This collaboration effort between the customer and all service providers is essential to the successful completion of difficult HPHT wells.

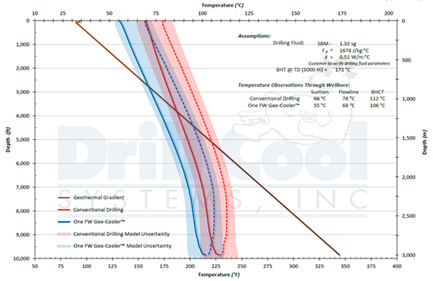

One of the most powerful tools Drill Cool has at its disposal is their vast experience with Thermal-Hydraulic Wellbore Modeling. Engineers with Drill Cool Systems have grown to be respected across the industry for their experience in modeling the thermal performance of the well and lending that experience to the team working on hydraulic optimization.

SERVICE TO OUR CUSTOMERS

Providing a valuable service to the customer is primary for Drill Cool Systems. The people of Drill Cool Systems, empowered with experience and the best equipment, carry that responsibility with them to each job location. At the highest level, the purpose of Drill Cool Systems on each project team and on each job site is to make that environment safer. A safe workplace involves the customer partnering with Drill Cool Systems to truly understand the temperature related risk they have to personnel, equipment, and the environment and continue to work with Drill Cool Systems to mitigate those risks.

Drill Cool Systems, Inc. has a strong commitment to provide a work place that protects the health and safety of their employees and the communities in which they work. Additionally, Drill Cool Systems takes seriously their stewardship of the environment in which they perform services.

The Goal of Drill Cool Systems is “Zero Incidents”

Each of the employees with Drill Cool Systems is committed to that goal at all times – at work and at home. Safety is much more than an attitude, a program, a process or a priority – it is part of the culture at Drill Cool Systems.

The ability of Drill Cool System to serve each customer is driven from their core values including:

SERVICE | SAFETY | ENVIRONMENT | HEALTH | INTEGRITY

Drill Cool's

THERMAL‑HYDRAULIC WELLBORE MODELING

DRILL COOL SYSTEMS IS AN INTEGRAL MEMBER OF THE WELL DESIGN TEAM

WE SHARE THE EXTENSIVE EXPERIENCE WE HAVE EARNED OVER THE PAST 35 YEARS WHILE OPERATING ON HIGH TEMPERATURE WELLS ALL OVER THE WORLD.

Your ability to understand and manage the temperature limitations of your HPHT drilling operations, especially those limitations of your critical safety equipment within each system, is essential to the successful and safe completion of your HPHT well.

The modeling and characterization of drilling conditions are essential to understanding the temperature related hazards of an HPHT well – risk that exists both within the wellbore and on surface. Due to the pressure-volume-temperature (PVT) relationship within the drilling system, a thermal hydraulic evaluation of the drilling plan is critical. Some temperature risks may be directly related to extreme pressure and flow conditions encountered within the wellbore.

It is essential that a thermal-hydraulic model be created of the drilling system. This model must be dynamically updated as both design conditions and field conditions continue to evolve. These models can be used to predict the benefit and value of surface temperature control equipment such as mud coolers.

Request a Wellbore Model for your project.

Drill Cool's

JOB‑SITE THERMAL RISK ASSESSMENT

SAFETY OF RIG PERSONNEL & EQUIPMENT IS OUR PRIORITY

TEMPERATURE RELATED RISKS ON AN HPHT WELL EXTEND BEYOND THE THERMAL STRESSES OF PERSONNEL WORKING WITHIN THE ENVIRONMENT.

Your ability to understand and manage the temperature limitations of your drilling operations is essential to the successful and safe completion of your well.

HPHT WELL TEMPERATURE RISKS

Our high temperature drilling engineers with HPHT experience look beyond the simple installation of a basic mud cooler or assumed specification for flowline temperature reduction.

Drill Cool Systems can help assess those temperature related risks and then develop solutions to completely mitigate, control and protect your operations from those risks.

Oil & gas and geothermal drilling have many risks and hazards associated with conventional operations. A hazard control program is an essential element to ensure adequate steps are taken to protect the people and the environment from exposure to system or substance.

Each hazard control program should include the training and the procedures required to monitor worker health and exposure to hazards such as temperature, pressure, chemicals, electricity, materials or substances, or other types of hazards such as motion, noise and vibration.